Skövde Slakteri

From steam to steam – but make it climate-smart

The mission

Skövde Slakteri has been operating for over forty years. For its production, the slaughterhouse needs steam something that was previously produced through the use of fossil fuels. In order to continue running a sustainable business, they decided to phase out the fossil fuel, replacing it with a biofuel: a pellet-fired plant for steam production.

Client:

Skövde Slakteri AB

Industry:

Food; meat and charcuterie

Solution/Product:

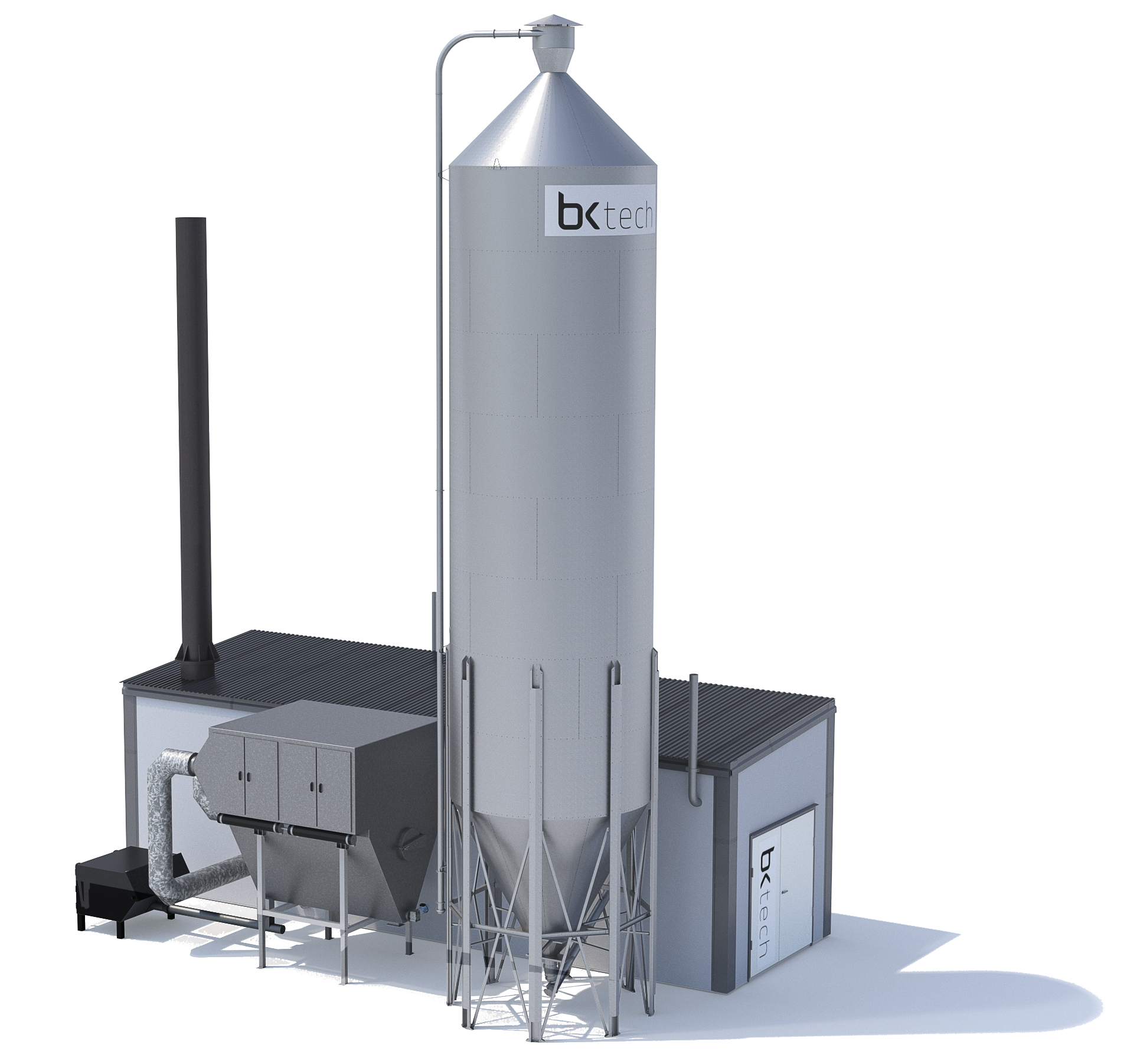

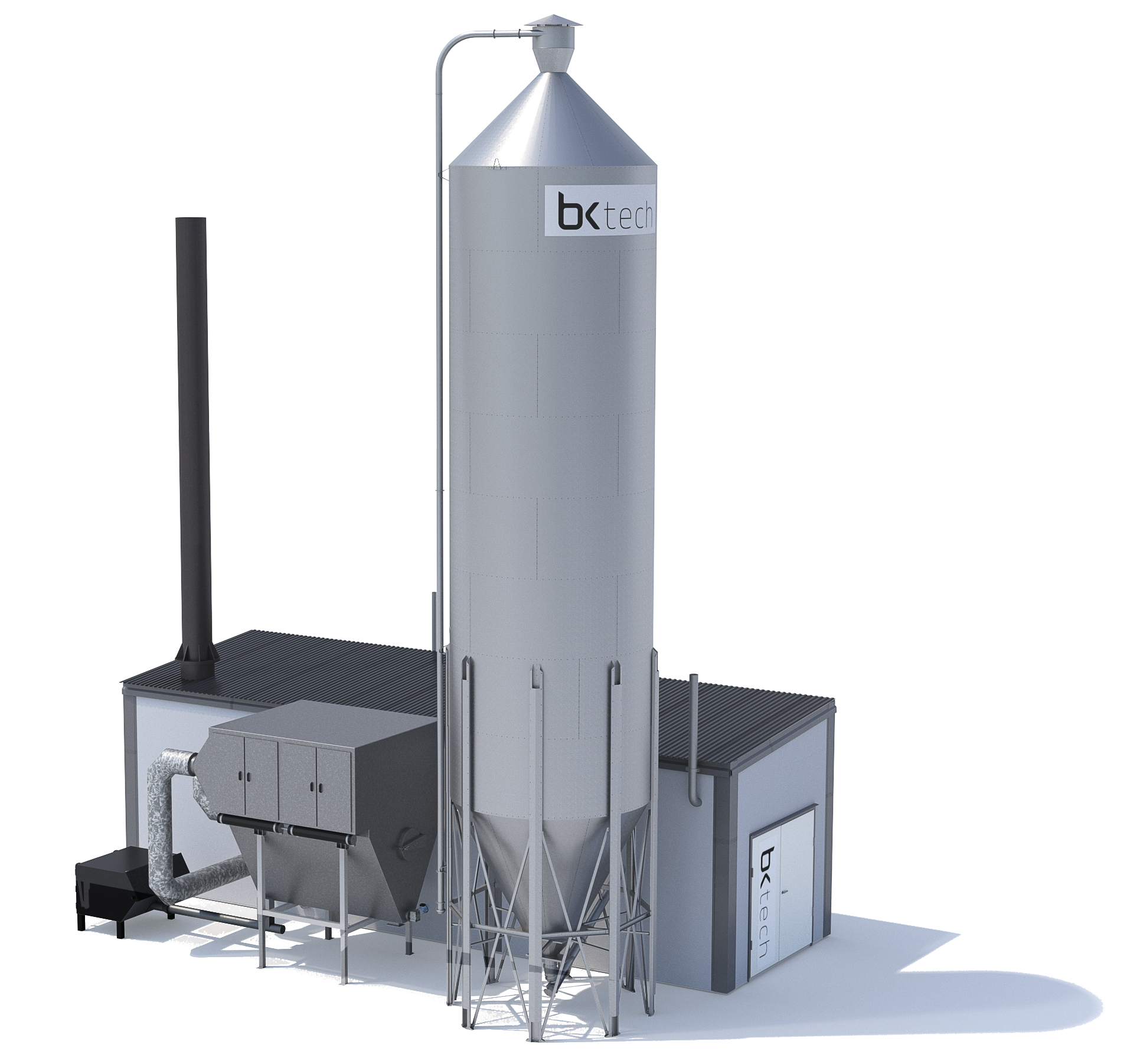

BKtech BioOne Steam 1,3 MW for steam production

Interesting facts:

Skövde Slakteri is Sweden's largest privately owned slaughterhouse, and works exclusively with Swedish farms and Swedish meats.

The process

The agreement between BKtech and Skövde Slakteri involves the delivery of a 1.3 MW modular bioenergy plant that will produce the steam needed for the slaughterhouse’s operations. Fossil fuel combustion will be phased out, to be replaced entirely by biofuel – wood pellets – in the new bioenergy plant.

Investing in bioenergy for the future

Skövde Slakteri has been in business for over forty years and has now made the decision to go fossil-free. Listen to Björn Hellner, Director of Maintenance, as he discusses sustainable production and describes what the collaboration with BKtech has been like.

The results

Since Skövde Slakteri is certified according to the GFSI standard FSSC22000, holds a KRAV certification and meets the standards of the EU organic logo , it is imperative to have a sustainable production throughout the chain. Therefore, the cooperation between BKtech and Skövde Slakteri is important from both a climate and certification perspective, and BKtech will deliver the new bioenergy plant in 2022 according to the agreement. We look forward to this partnership and our future together with Skövde Slakteri.

-93%

-34%

Generic fuel savings, not related to a specific reference case.

Find out how much you can cut costs

By switching from fossil fuels to fossil-free bioenergy, you can benefit both the climate and your finances. Make a specific calculation for your company and find out how much you can save in terms of both CO₂ and budget.

Make your calculationMore cases from the food industry

”Lulles” – Ludvig Sörensen

Atria Borås

Falköpings Mejeri

Gudruns kött & charkuterier

Guldfågeln AB

High Coast Distillery

Krönleins Bryggeri AB

Nya Lantfågel på Österlen

Skövde Slakteri

Stranda Kyckling AB

Svenska Lantchips AB

Tevsjö Destilleri

Vätternpotatis

Wermlands Mejeri

Further companies that use our solutions